Whatsapp Us For Price: +86 150 5425 3293

Quartz Stone Slabs Common Quality Problems

Quartz Stone Slabs have common quality problems such as color differences, Impurities, Cracking, and splice gaps.

1. Color Difference:

Quartz stone slab resin content is low, more than 90% of it is quartz, Quartz is mined from natural mines, that is, more than 90% of its components are from nature.

Although the color of quartz in most mines is white, there are also differences, some are yellow, some are blue, and sometimes the color of quartz from the top of the mountain and the tail of the same mine is slightly different. According to this situation, the quartz stone slab generally has a slight color difference, After passing the factory inspection, the color of the slab of the same product batch is basically the same (but compared with the standard of ordinary artificial stone, it is difficult to do seam stitching), and the slab of different product batches will have a slight color difference.

When connecting slabs, they must be from the same batch of orders, and different batches of slabs are not allowed to be connected.

If there is a large color difference after the connection with the batch slab (slight color difference is a normal phenomenon), please confirm whether the grinding degree of the slab is consistent on the spot, and whether the grinding degree of the dark slab will directly affect the color difference. Secondly, use a wet rag to wipe and confirm. Under natural light, it is best to stand at the same Angle to observe.

2. Impurities:

Because more than 90% of the composition of the quartz stone slab is natural, quartz ore will have a yellow skin, so the control of impurities in the quartz sand is difficult compared with the raw materials of ordinary artificial stone.

In addition, the hardness of quartz stone slabs is high, so the repair process is difficult to ordinary artificial stone slabs. In general, the surface of the quartz stone slab will have 1mm impurity, that is a normal phenomenon, Sizes bigger than this or dazzling impurities can be removed by the method of dredging.

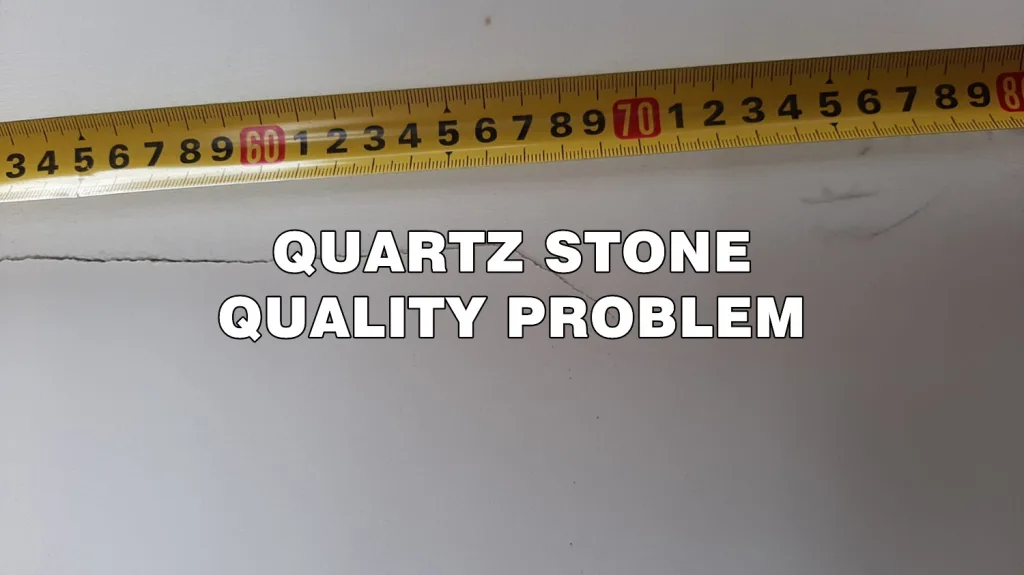

3. Cracking:

Quartz stone slab is a product formed by vacuum at high pressure, low resin content. Quartz stone has high hardness, and lower toughness than ordinary artificial stone.

Although quartz stone countertops contain composite agents to improve material toughness, and have relatively high impact resistance, they still needs avoid

- Being hit

- Frequent percussion

- Heavy compression on the countertop hanging part, especially the weak part of the countertop. Such as near the stove, near the basin, corner parts, splicing parts, the middle part of the large-span cabinet, etc. In general, all corners of the table should be kept above R25 rounded corners;

In Additon,

- The four sides of the stove and the mouth of the basin should be straight edges of the gong machine.

- The front skirt, back stop underwater stop should be glued firmly.

- Do not connect in the opening position or corner.

- Cabinet installation should be horizontal.

- The maximum span of the table support should not exceed 600mm.

4. Splice Gap:

The quartz stone slab has high hardness and low resin content, which is closer to natural stone. After two quartz stone slabs are connected, the splicing place will generally be like a trace, but it is not easy to see without a careful look, and it does not affect the appearance. In general, quartz stone products can achieve seamless stitching under the production of skilled quartz stone processing masters.

Useful Links

Quartz slabs for wholesale all designs